Screen cleaners are commonly spherical or cube-shaped pieces placed within each of a sieve tray’s compartments between the screen mesh and the tray’s backwire. While material flows through the sieve, the sifter’s drive motion causes these screen cleaners to bounce freely between screen and backwire, gently tapping the screen and preventing product from sticking and “blinding” the screen openings. This ensures optimal material flow through each of the sieve stack’s separations.

Screen cleaners are available in multiple material options. Because cleaners, though necessary to the sifting process, have a limited service life, they can degrade, causing small pieces to integrate with the material. Different colors are thereby useful as a quality control measure to detect when cleaners, screen trays, and sieves may need maintenance or repairs. Food-grade and metal-detectable cleaners are also beneficial for this purpose.

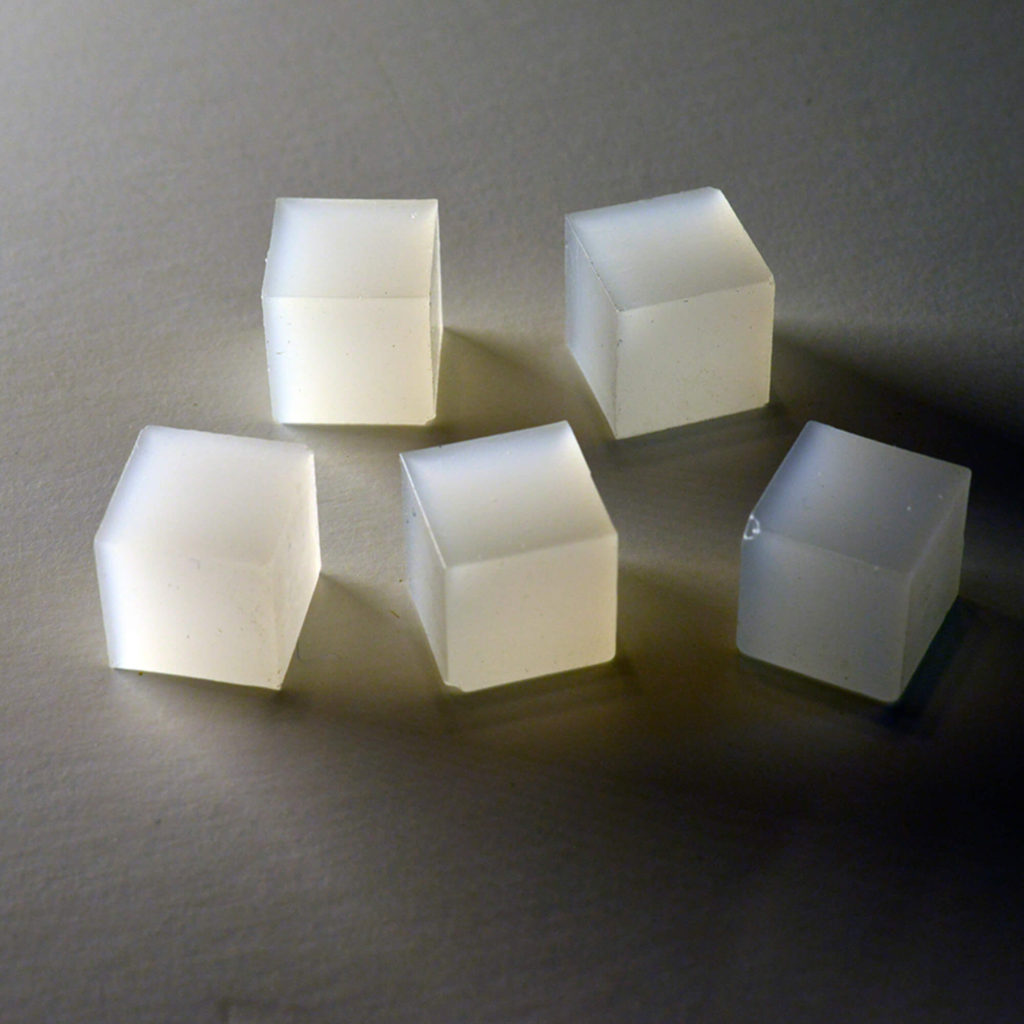

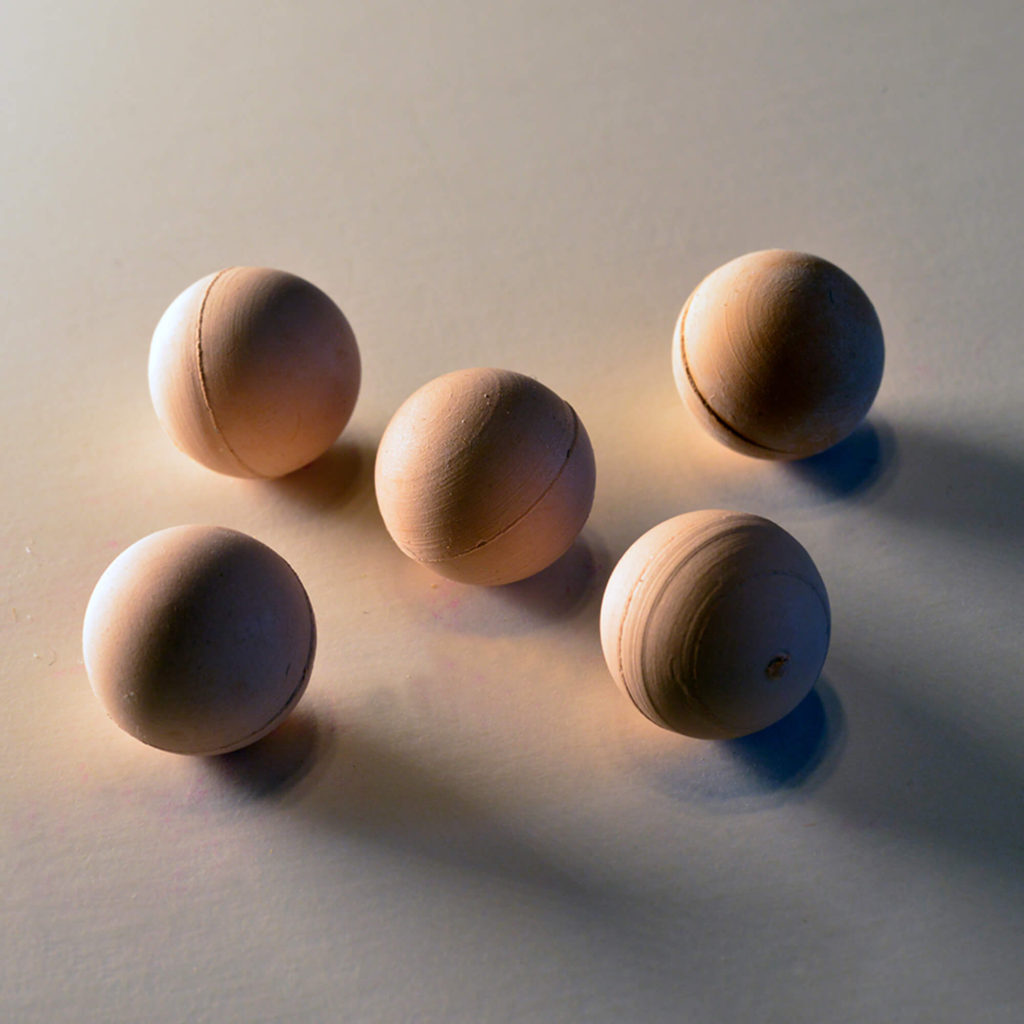

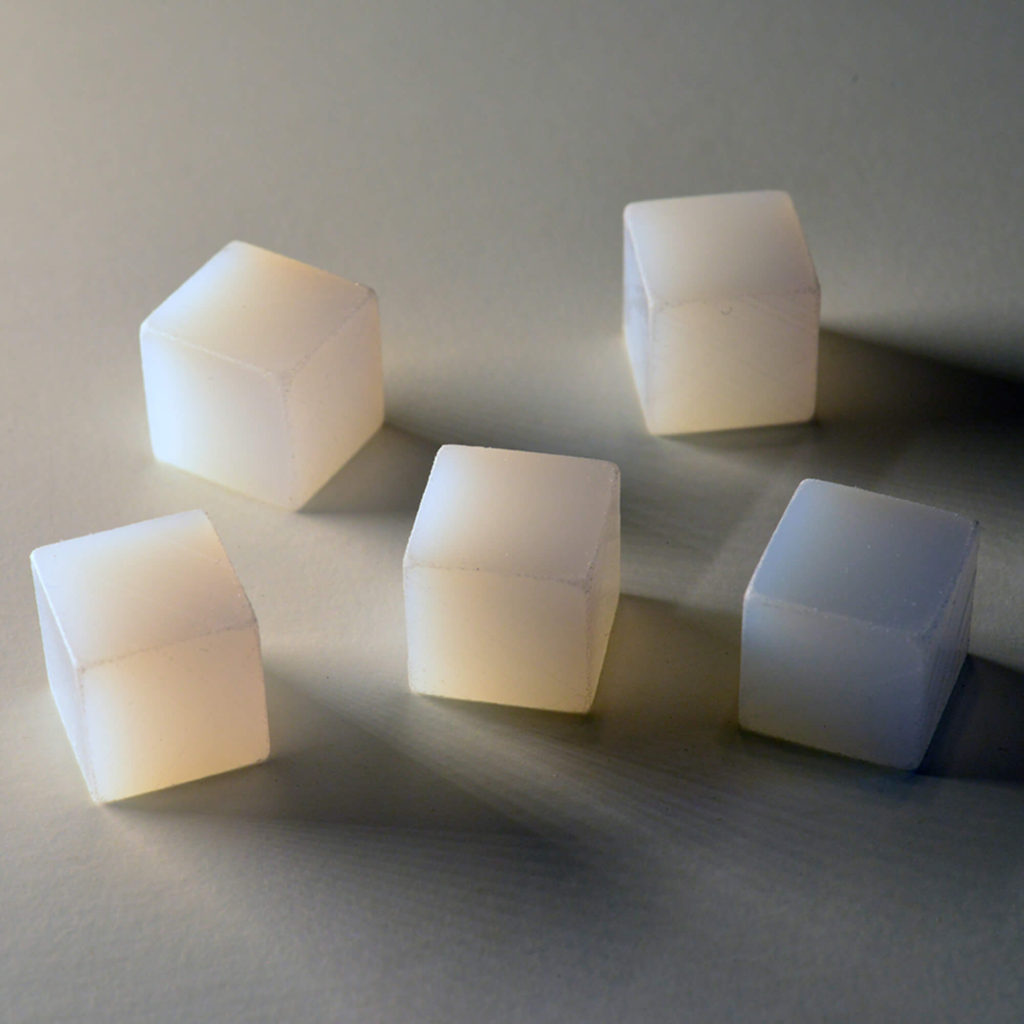

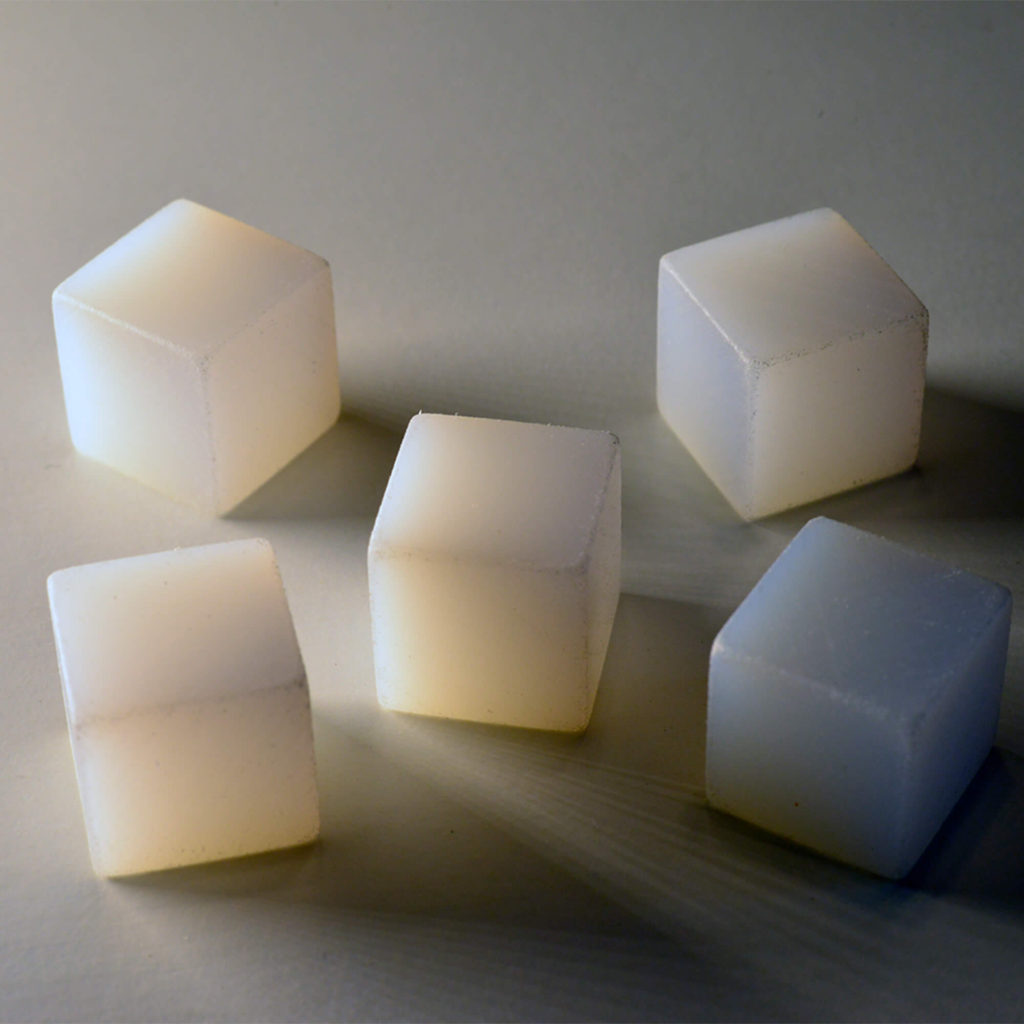

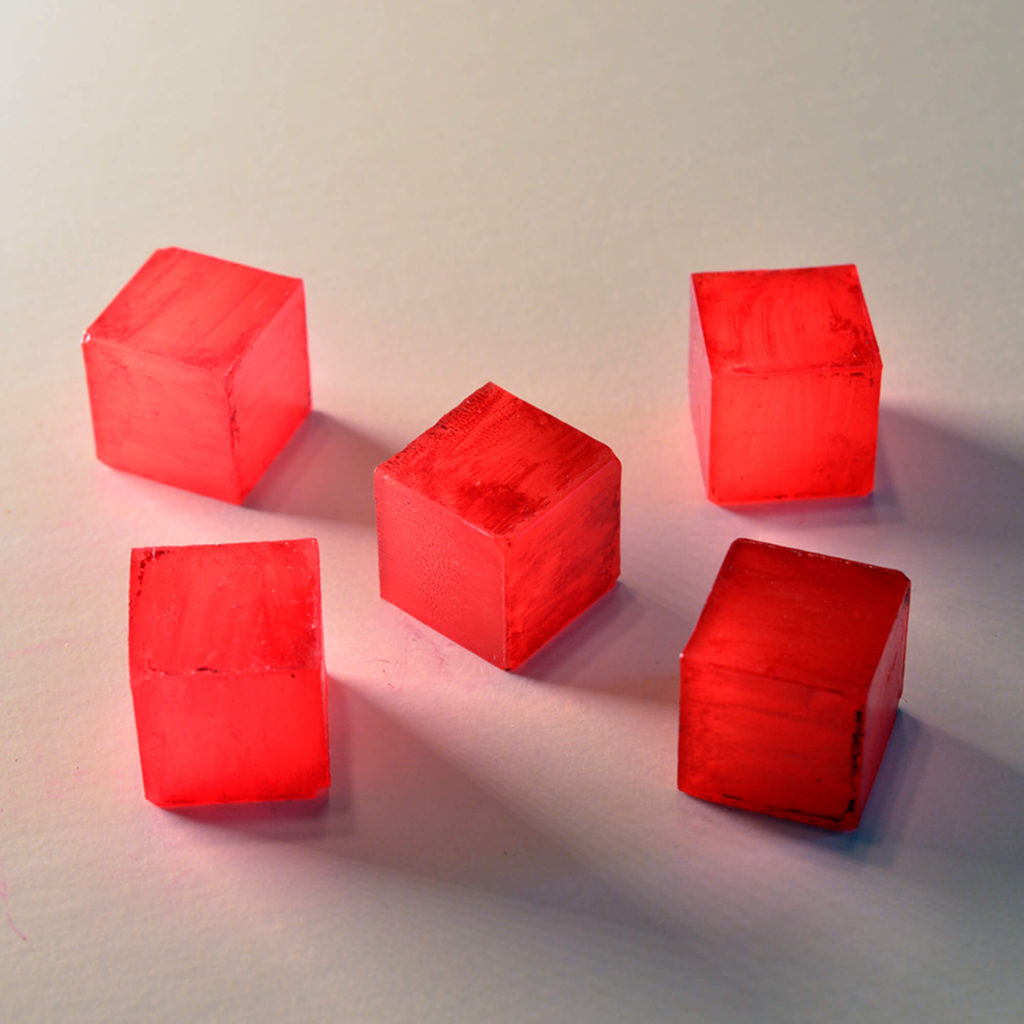

Standard screen cleaners include:

- Poly Ball Cleaners

- Poly Cube Cleaners

- Rubber Ball Cleaners

- Silicone Ball Cleaners

- Nylon Ball Cleaners

- 1/2” UHMW Cleaners

- 5/8” UHMW Cleaners

- Metal Detectable Ball Cleaners

- Metal Detectable Cube Cleaners

- Colored Ball Cleaners

- Colored Cube Cleaners

- Triangle Knob Screen Cleaners