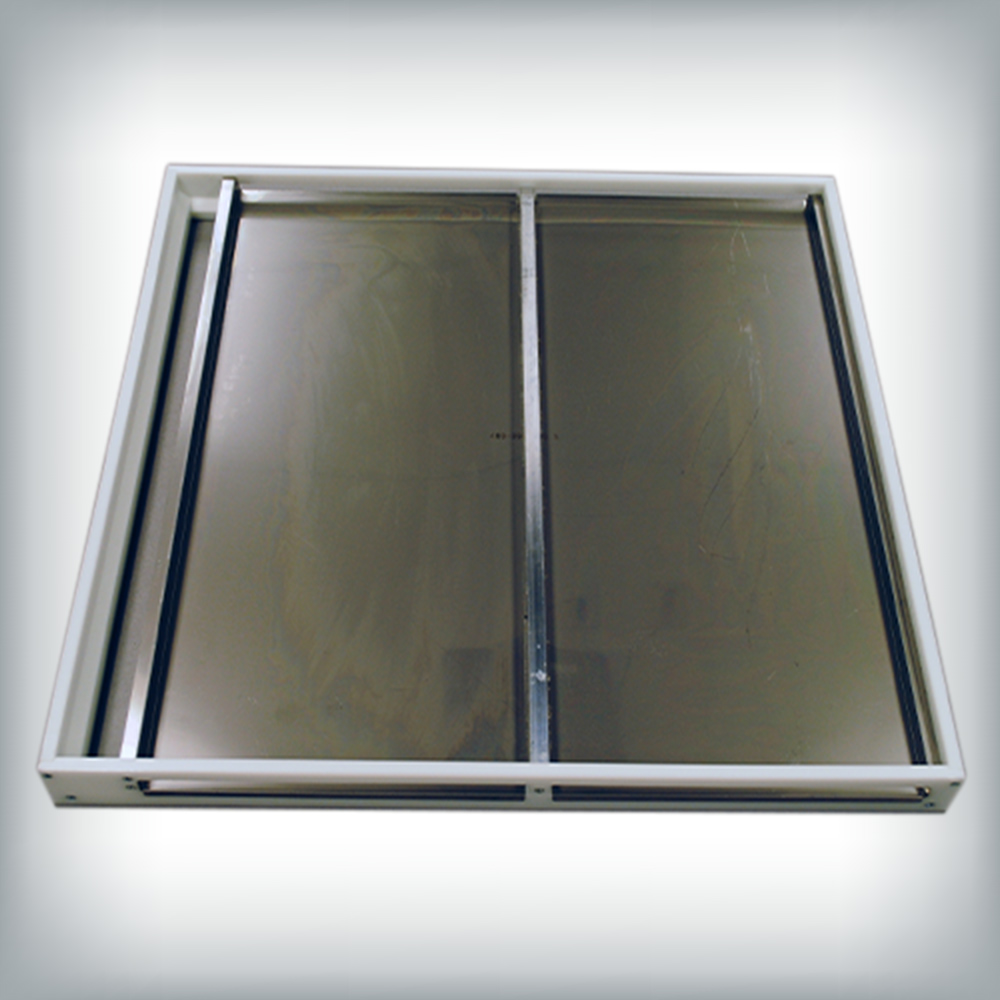

The NOVA sieve is designed to eliminate common issues by increased simplicity. Through this simplified design, the number of required components is reduced, offering improved durability and reduced risk of contamination over the course of your sieve stack’s operating life. The use of the metal insert frame and combination cleaners reduces overall sieve height, which allows for more sieves or deeper sieves that allow increased material flow in the sifter compartment. During operation, the high-performance cleaners clean both pan and screen simultaneously, making the NOVA sieve a superior choice for high-capacity operations that do not sacrifice flow quality.

Sieves

Separated by Excellence

NOVA Sieve

- The use of only one NOVA cleaner per tray compartment is a superior method to create more sanitary conditions.

- The aluminum lift-out frame offers a thinner profile than wooden frames, increasing net screen area per stack.

- The aluminum insert tray provides a stable and wear-resistant support for screen attachment, resulting in optimized conditions for screen tension longevity.

- Improved sanitation and reduced risk of product contamination with use of glue-on attachments over stapled attachments.

- Eliminated backwire reduces hazard of deterioration or fastener loss.

- Unique engineering overall reduces maintenance requirements.

- Space-effective, thinner design allows either increased number of sieves, improving separation efficiency, or deeper sieves, increasing conveying capacity.

- Improved product flow.

| Sieve Size | Type | Throat Size | Side Channel Width | Number of Compartments | Net Screen Area

(ft2) |

| 24-11/16″

627 mm |

2 Side Channel | 1-5/8″

41 mm |

1-5/8″

41 mm |

4 | 2.8 (.26 m²) |

| 24-11/16″

627 mm |

Full Cloth | 1-5/8″

41 mm |

– | 6 | 3.2 (.30 m²) |

| 25-3/16″

640 mm |

2 Side Channel | 47 mm

1-7/8″ |

52 mm

2″ |

4 | 2.7 (.25 m²) |

| 25-3/16″

640 mm |

Full Cloth | 47 mm

1-7/8″ |

– | 6 | 3.3 (.31 m²) |

| 28-3/4″

730 mm |

2 Side Channel | 2-1/4″

57 mm |

2″

51 mm |

6 | 3.6 (.34 m²) |

| 28-3/4″

730 mm |

Full Cloth | 2-1/4″

57 mm |

– | 9 | 4.4 (.40 m²) |

* The above specifications denote standard dimension and design. Please contact Great Western Manufacturing to discuss your operation’s specific requirements.