Blending

Separated by Excellence

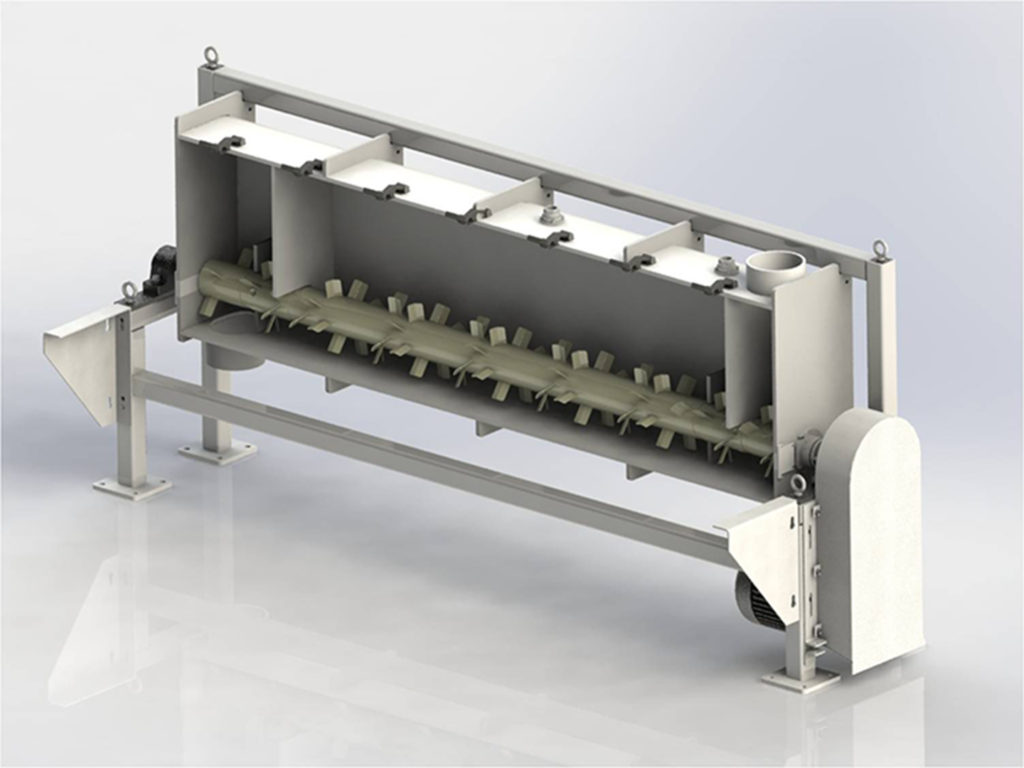

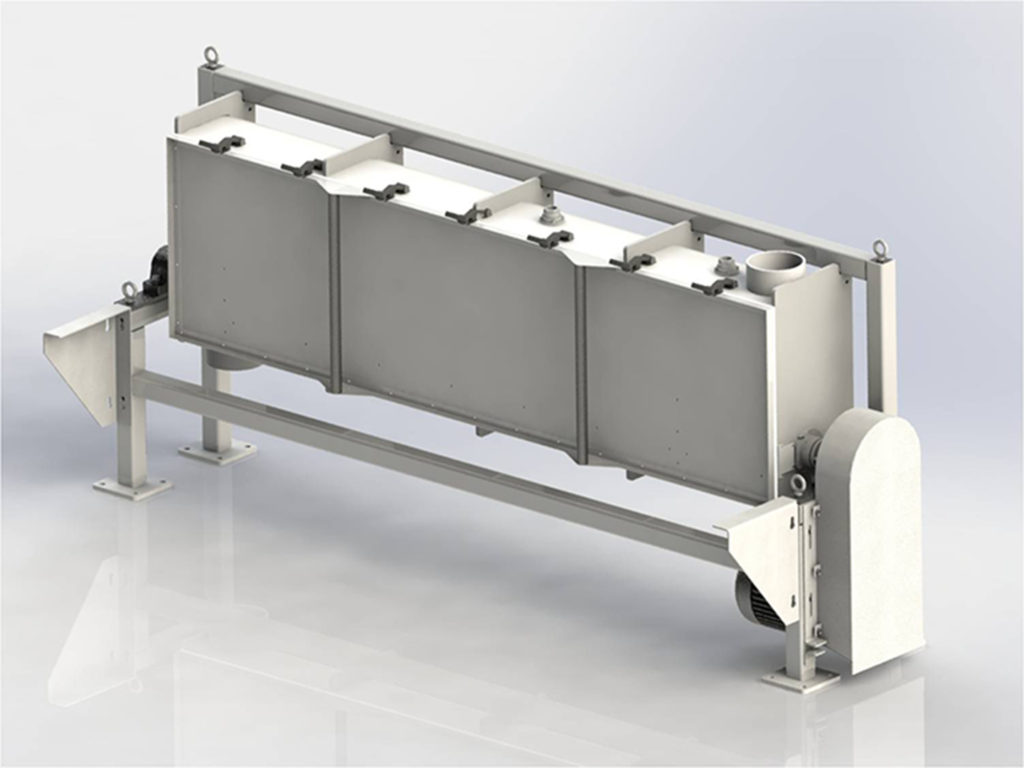

GW Original Agitator/Blender

- Polyvinylchloride housing construction provides durability against adverse effects of chlorine or other gasses.

- Smooth interior without seams or crevices improves product flow while eliminating accumulation points.

- Flexible size and rotor construction to maximize effectiveness for your production requirements.

- Perfectly balanced rotor to increase operational longevity.

- Dust-tight tongue and groove joints and Teflon packing seals ensure precise and secure sealing to prevent leakage of gasses or materials.

- Drop bottom enables easy disassembly and thorough, rapid cleaning

- Excellent mixing and conveying action for improved quality control.

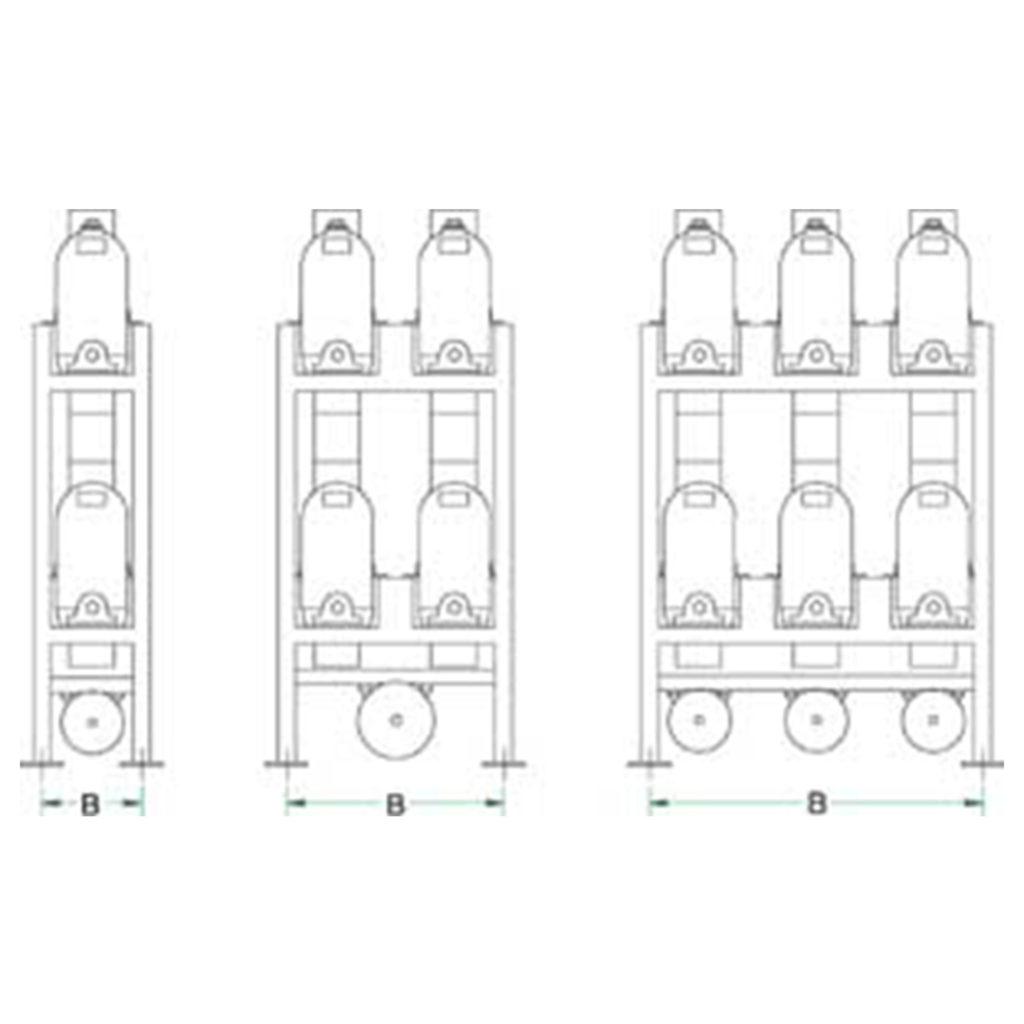

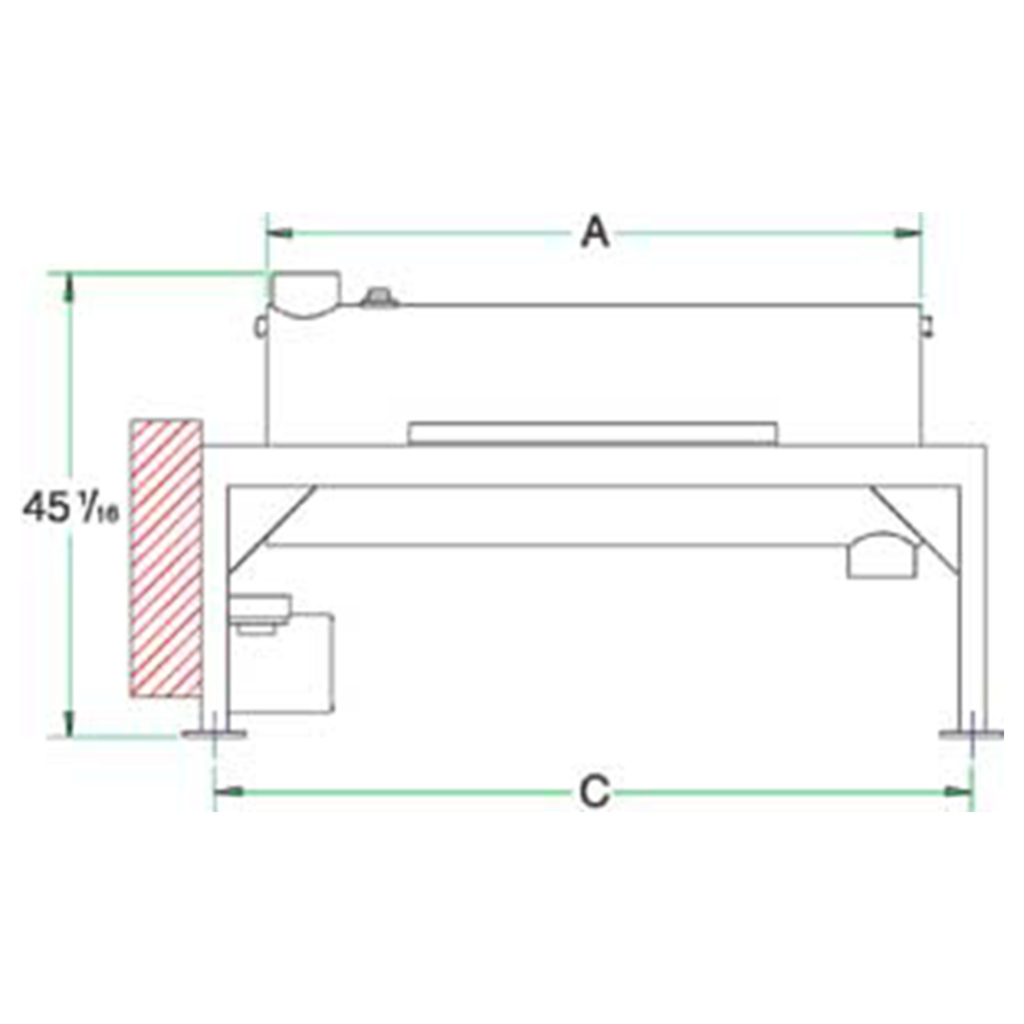

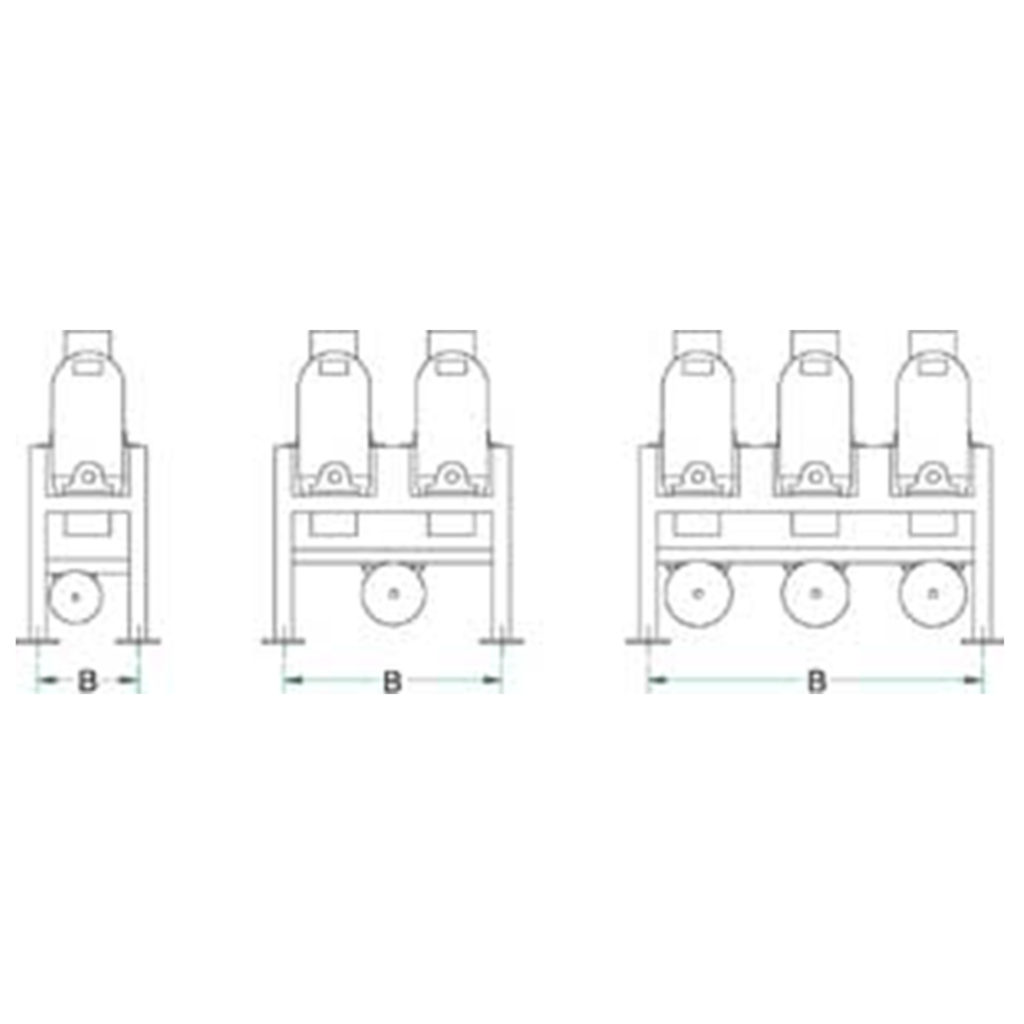

Single-pass arrangements are recommended when treatment rates do not exceed 1 oz of chlorine per cwt (0.6 g/kg). Double-pass arrangements are recommended for rates above 2 oz of chlorine per cwt (1.2 g/kg). Rates between 1 and 2 oz of chlorine per cwt should be reviewed with Great Western prior to final equipment selection. The maximum conveying rate of each housing assembly is 200 cwt per hour.

Single Pass Units

| Model | A | B | C | Horsepower |

| 111 | 63-3/4” | 14-3/8” | 73-3/4” | 1-1/2 |

| 121 | 63-3/4” | 31-1/4” | 73-3/4” | 3 |

| 211 | 75-3/4” | 14-3/8” | 85-3/4” | 3 |

| 221 | 75-3/4” | 31-1/4” | 85-3/4” | 5 |

| 231 | 75-3/4” | 48-1/8” | 85-3/4” | 3 @ 3 |

| 311 | 87-3/4” | 14-3/8” | 97-3/4” | 3 |

| 321 | 87-3/4” | 31-1/4” | 97-3/4” | 5 |

| 331 | 87-3/4” | 48-1/8” | 97-3/4” | 3 @ 3 |

Double Pass Units

| Model | A | B | C | Horsepower |

| 212 | 75-3/4” | 14-3/8” | 85-3/4” | 5 |

| 222 | 75-3/4” | 31-1/4” | 85-3/4” | 10 |

| 232 | 75-3/4” | 48-1/8” | 85-3/4” | 3 @ 5 |

| 312 | 87-3/4” | 14-3/8” | 97-3/4” | 5 |

| 322 | 87-3/4” | 31-1/4” | 97-3/4” | 10 |